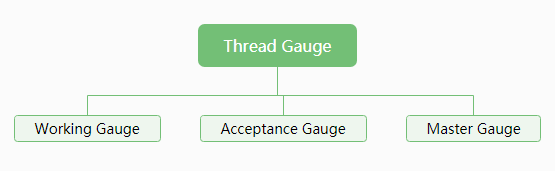

Isicelo And Vukusulwa Of Thread Gauge

(1) Umgomo wokusetshenziswa kwegeji (1) Umthetho ojwayelekile.

Ekuhloleni kwentambo nsuku zonke, kuvame ukuphikisana ngokusetshenziswa kwamageji. Lokho kusho ukuthi, lapho intambo ihlolwe ngegeji entsha negeji endala, kungavela iziphetho ezahlukahlukene zokuhlola.

(2) Izinga lichaza ukuthi:

Kusetshenziswa i-thread gauge (i-ring gauge ne-plug gauge) ukuhlola intambo ye-fastener yezohwebo ukuphela kwendlela yokulinganisa enganquma ukuthi umkhiqizo wamukelekile noma cha.

Lapho ama-gauge wentambo nezinsimbi zokulinganisa kusetshenziswa ekuhloleni, akukho-fastener ezokwaliwa uma usayizi wentambo uphakathi kwemikhawulo ebekiwe. Kunqume ukubheka ukufaneleka kwemicu ngegeji yezintambo.

(3) Umsebenzi wokuhlola i-gauge.

I-Go isetshenziselwa ukubheka ubukhulu obukhulu bomzimba (isb. Ubukhulu be-pitch esebenzayo) ngentambo.

(I-LO ring gauge) noma i-ga gauge gauge (i-gauge gauge gauge) isetshenziselwa ukubheka ububanzi be-pitch eyodwa yentambo.

Hlola nge-gauge ebushelelezi yendandatho noma i-gauge ye-plug elula. Kuvunyelwe futhi ukubheka ububanzi obukhulu bomucu wangaphandle nobubanzi obuncane bomucu wangaphakathi nge-gauge yesikhombi (i-micrometer noma i-caliper).

Igama lokuhlukaniswa kwe-Gauge nohlelo lokusebenza.

(1) Igeji yokusebenza

Igeji yentambo esetshenzisiwe ekukhiqizeni, ekwenziweni nasekuhloleni intambo yokuqinisa.

(2) Igeji yokwamukela

Igeji yentambo esetshenziswa umnyango wokuhlola noma omele umsebenzisi lapho amukela intambo yokuzila.

(3) I-Master Gauge

Igeji yentambo esetshenziswa umnyango wokuhlola noma omele umsebenzisi lapho amukela intambo yokuzila. Hlola ukuthi i-gauge yochungechunge yokusebenza iyafaneleka yini ekukhiqizeni nasekuhloleni.

Isiqu se-gauge yeringing ring siqinisekiswa yi-gauge yokuhlola intambo (ukwahlulela okuhle).

I-Thread plug gauge enentambo yokulinganisa inaliti yenaliti iyafaneleka (ukwahlulela ngobuningi).

Izidingo zokusetshenziswa kwegeji

(1) Indawo yokubekezelelana kokuklanywa kwentambo ingaphakathi kobukhulu bomkhawulo wentambo yomkhiqizo. Ukuze uxazulule impikiswano ebangelwe umehluko wenani lomkhawulo langempela (ukugqoka okusha nokudala) kwamageji amasha namadala asetshenziswayo.

(2) Ku-American Standard ANSI B1.2: 2007 nakwamanye amazwe i-ISO1502 ejwayelekile, kuphakanyiswa nokuthi i-screw thread gauge ihlukaniswe yaba yizinhlobo ezimbili zamageji: I-Working Gauge ne-gauge yegeji (i-American scalar gauge x ukuphambuka okuhle nokubi ).

(3) igeji yokusebenza negeji yokwamukela.

|

Ukwahlukanisa |

Ububanzi besicelo |

Isimo sokulinganisa |

|

Igeji yokusebenza |

I-gauge yokuhlola intambo yenqubo yokukhiqiza | Sebenzisa okusha noma okuncane okugqokwa ngegeji yezintambo |

| Sebenzisa igeji yocingo lokugcina elidala noma eligugile | ||

|

Igeji yokwamukela |

Igeji yentambo esetshenziswa umnyango wokuhlola noma omele umsebenzisi lapho amukela intambo yokuzila. | Sebenzisa okudala noma okugqokwa ngegeji yochungechunge |

| Sebenzisa igeji yokuphela yocingo entsha noma engagugile |

Intambo yokuhlola intambo yemikhiqizo yokuqinisa

(1) I-gauge yokuhlola intambo ihlukile. Ngokuya nge-GB, amazinga we-ISO, i-DIN, i-ANSI, i-BS, isifinyezo sokuhlolwa kwe-gauge yomugqa simi kanje:

|

Intambo |

uhlelo lwe-metric | Uhlelo lwaseMelika | Uhlelo lwaseBrithani |

|

Intambo Yangaphandle |

6g | 2A | M |

|

Intambo Yangaphakathi |

6H | 2B | N |

(2) Go / No go gauge

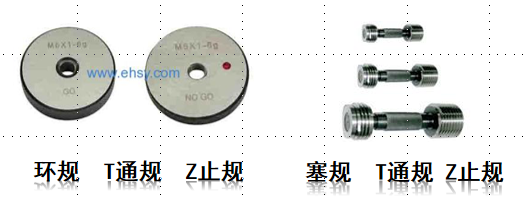

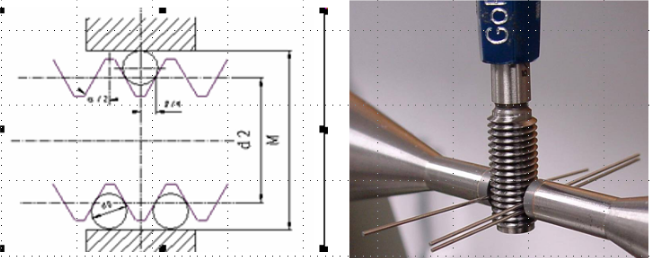

Ekuhlolweni kwentambo kwama-fasteners entengiso, ama-gauges asetshenzisiwe yi-ring gauge (ehleliwe futhi eguquguqukayo), i-plug gauge, ne-micrometer, esetshenziselwa ukwahlulela okufanelekile kweziqu.

Indandatho ye-Ring gauge

Uhlobo umile ashintshekayo

Umsebenzi nokusetshenziswa kwe-metric thread gauge

|

Kala |

Ikhodi |

Umsebenzi |

Imiyalo |

|

|

Amantongomane |

Ngokuqeda ipulaki gauge |

T |

Bheka ububanzi be-pitch nobubanzi obukhulu bezintambo zangaphakathi | Ukugoqa kwamahhala ku |

| I-gauge yepulagi engapheli |

Z |

Bheka ububanzi be-pitch eyodwa yentambo yangaphakathi | Misa ngentambo emi-2 | |

|

Amabhawodi |

Ngokuqeda indandatho yokulinganisa |

T |

Bheka ububanzi be-pitch nobubanzi obuncane bomucu wangaphakathi | Ukugoqa kwamahhala ku |

| Igeji yendandatho engapheli |

Z |

Bheka ububanzi be-pitch eyodwa yentambo yangaphakathi | Misa ngentambo emi-2 | |

|

I-Master plug gauge

|

I-Master through end plug gauge -Ukusebenzisa |

TT |

Hlola ububanzi be-pitch yangempela ye-gauge yeringing ring entsha | Ukugoqa kwamahhala ku |

| I-Master through end gauge gauge - Hhayi-ukuphela |

TZ |

Hlola ububanzi bepitela eyodwa yegeji yeringing entsha | Isikulufa ngentambo engu-1 | |

| I-Master through end plug gauge - Ukulahlekelwa |

TS |

Hlola ububanzi be-pitch eyodwa ye-gauge yendandatho esetshenzisiwe | Isikulufa ngentambo engu-1 | |

| I-gauge ye-plug ye-master not-go-end - Iyadlula |

ZT |

Hlola ubukhulu be-pitch yangempela yegeji entsha yezingcingo ezingapheli | Ukugoqa kwamahhala ku | |

| I-gauge ye-plug ye-master not-go-end - Not-go-end |

ZZ |

Hlola ububanzi bepitela eyodwa yegeji yering entsha engapheli | Isikulufa ngentambo engu-1 | |

| I-gauge ye-plug ye-master not-go-end - Ukulahlekelwa |

ZS |

Hlola ububanzi bepiyela elilodwa legeji yendandatho engapheli | Isikulufa ngentambo engu-1 | |

Umsebenzi nokusetshenziswa kwe-gauge yensimbi yaseMelika

|

Kala |

Ikhodi |

Umsebenzi |

Imiyalo |

|

|

Amantongomane |

Ngokuqeda ipulaki gauge |

HAMBA |

Bheka ububanzi be-pitch nobubanzi obukhulu bezintambo zangaphakathi | Ukugoqa kwamahhala ku |

| I-gauge yepulagi engapheli |

AKEKHO |

Bheka ububanzi be-pitch eyodwa yentambo yangaphakathi | Misa imicu engu-3 | |

|

Amabhawodi |

Ngokuqeda indandatho yokulinganisa noma uhlobo olungaguquguqukayo |

HAMBA |

Bheka ububanzi be-pitch nobubanzi obuncane bomucu wangaphakathi | Ukugoqa kwamahhala ku |

| Igeji yering not-go-end noma uhlobo oluguquguqukayo |

AKEKHO |

Bheka ububanzi be-pitch eyodwa yentambo yangaphakathi | Misa imicu emi-3 | |

|

I-gauge yendandatho enkulu

|

I-Master plug gauge |

HAMBA UNGAYI |

Hlola ububanzi be-pitch yesilinganiso se-gauge ring ring | Bheka isigaba esigcwele sentambo nentambo |

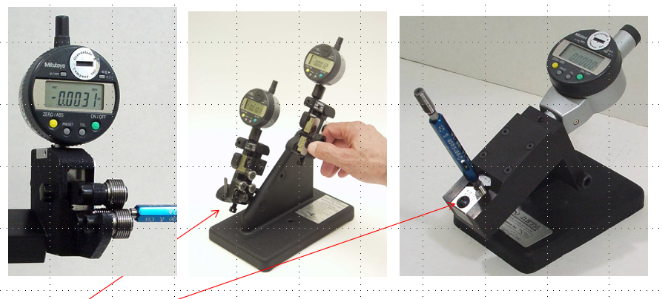

I-indicator gauge umkhuba okhulayo emazweni angaphandle. Kuyithuluzi elisheshayo lokuhlolwa kweziqu zemicu. Ngakolunye uhlangothi, ingenza isahlulelo sekhwalithi, ngakolunye uhlangothi, ingalinganisa ubukhulu bemingcele.

I-gauge yesibonisi sentambo

120°Ikhanda lokulinganisa ububanzi obunamasondo amathathu

Indlela ye-Micrometer yokulinganisa ubukhulu obukhulu

Isici:

• Ukutholwa kobubanzi be-pitch eyodwa

• Akunakwenzeka ukuthola ububanzi obuphakathi besenzo

• Intambo yangaphakathi ayitholakali

• Ukunemba okuphansi, okusetshenziselwa ukukalwa kwentambo ngokunemba okuphansi

Ukuqinisekiswa kwegeji yeringing

(1) Kunezindlela ezimbili zokulinganisa i-gauge yensimbi

Kuyisinqumo sekhwalithi yokulinganisa i-gauge yensimbi yokusebenza ngentambo ebheka i-plug gauge.

Kuyisinqumo esilinganiselwe ukusebenzisa insimbi yokulinganisa ubude, imicroscope yethuluzi le-wangei, nezinsiza zayo (njengehhuku lokulinganisa langaphakathi, ibhola lokulinganisa, iringi yokuhlola, njll.).

(2) Izindlela nezidingo zokulinganiswa kwentambo yensimbi

Zonke izilinganiso zezindandatho zentambo kufanele zihlanzeke phakathi kwemicu, futhi akukho oyela nokungcola okuvunyelwe ukunamathisela ezintanjeni.

Yonke igeji yendandatho nentambo kufanele ibe sesimweni esihle, futhi akukho sibazi noma isici esivunyelwe.

Thatha igeji yokulinganisa ehambisana negeji yeringing threaded, bese ugoqa ukuphela kwegeji yegeji yegeji kugeji yokukala (iring gauge) ngokushelela, kodwa hhayi igeji engapheli (indandatho yokulinganisa).

Isiphetho segeji lesheke lesikali se-plug esilingana ne-gauge yeringing gauge asikwazi ukufakwa ku-gauge go (ring gauge) noma i-ga-stop gauge (gauge ring). Lapho uhlola futhi uhlola i-gauge yensimbi, kuvunyelwe ukubhekisa emazingeni afanele enani lamazinyo igeji yokuhlola engangena kwigeji yeringing.

Ngemuva kokufundwa kokuhlolwa, faka imishini yokulinganisa ibuyele endaweni yayo ukugwema ukulimala.

Igeji ye-plug ayikwazi ukuqhutshwa ngamandla lapho kubhekwa i-angle yentambo ne-pitch.

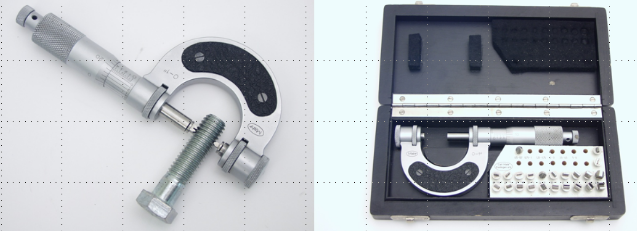

Isilinganiso samaphini amathathu sephayiphu yensimbi

(1) Pitch ubukhulu ukusebenza ngentambo plug gauge.

Indlela yezinaliti ezintathu ingasetshenziselwa ukuhlolwa. Ngokuya nge-P (iphimbo) nentambo engeli (α) yegeji yensimbi, kukhethwa ubukhulu bezinaliti obungcono ukunquma

ikhwalifikheyidi ye-screw plug gauge.

(2) Ifomula ehamba phambili yezinaliti ezintathu nokukala.

Ububanzi obukhulu bezinaliti ezintathu

|

intambo engela α ° |

Ifomula yokubala eyenziwe lula |

Isicelo |

|

60° |

d0= 0.577P |

Intambo yeMetric / intambo yaseMelika |

|

55° |

d0= 0.564P |

Intambo yaseBrithani |

Ifomula yokubala yesilinganiso senaliti ezintathu

|

Intambo |

Ifomula yokubala |

|

60°Intambo yeMetric / intambo yaseMelika |

d2= M-3d + 0.866P |

|

55°Intambo yaseBrithani |

d2= M-3.1657d + 0.9605P |

Inqubo yokukala

Isinyathelo 1: Khetha izinaliti ezintathu ngokuya ngefomula engcono kakhulu ngokuya kwephimbo

Isinyathelo 2: Khetha izinaliti ezintathu ezifanele

Isinyathelo 3: Bala inani le-a ngokuya ngefomula

Isinyathelo 4: Qhathanisa amanani alinganisiwe futhi abaliwe namapharamitha ajwayelekile bese ufinyelela isiphetho.

7. Ukusetshenziswa nokugcinwa kwegeji

• Ingxenye yokulinganisa yegeji izobe ingenakho ukugqwala nokungcoliswa;

• Ukuxhumana phakathi kwegeji nesibambo kufanele kuqine;

• Ubulukhuni bungu-58 HRC~65 HRC;

• Ubukhulu bokubekezelelana begeji buhlangabezana nezidingo ezijwayelekile;

• Ubukhulu begeji ngu-0.32μm;

• Yenza ukuhlolwa kweviki ngesimo sokusetshenziswa

• I-plug gauge kufanele ihlolwe kungakapheli izinyanga eziyi-4-6 isetshenziswe ngabasebenza ezimbonini;

• Iring gauge ingasetshenziswa izinsuku ezingama-20 kuya kwenyanga e-1 efemini futhi kufanele ihlolwe.

• Sungula i-akhawunti elungile yokusebenzisa igeji;

• Kufanele ihlukaniswe ibe yigeji yokusebenza kanye negeji yokwamukela.

Isikhathi Iposi: Dec-04-2020